Steel is a metal that is widely used in engineering. There are many different alloys that can be used for a variety of applications across industries. One such area is the automotive industry, which offers many applications for steel alloys as they are used in a variety of different components in vehicles.

How is steel used in the automotive industry?

All in all, the automotive industry uses stainless steel for two things – the durability of the material and the quality it provides. Stainless steel will become increasingly prominent as the automotive industry demands a combination of strength, efficiency, performance, and portability. Below are some applications of stainless steel in the automotive industry.

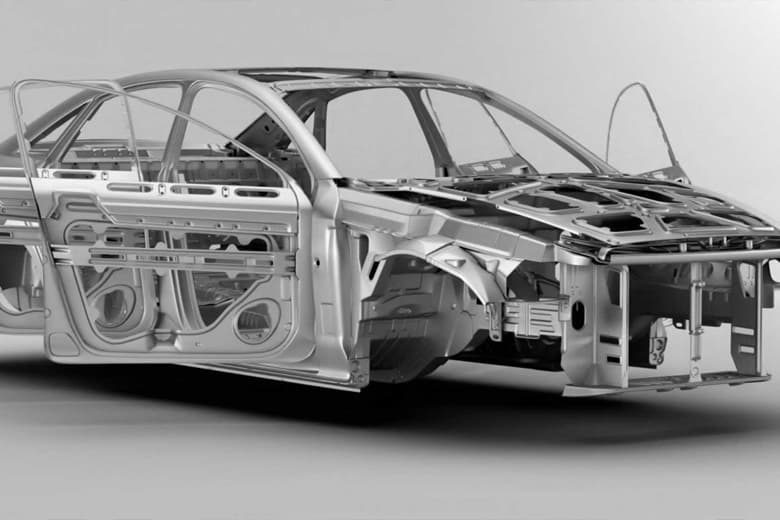

Lightweight Integrated Components

Car Frame

Corrosion Resistant Parts

Visual Design And Appeal

Benefits of using steel in the automotive industry

- Contains recycled steel and is endlessly recyclable.

- Has lower CO2 life cycle emissions than any other automotive material.

- Enables engineering of crash-resistant structures.

- High-strength steels enable light but stronger vehicles.

- Lightweight therefore fuel efficient.

- Durable and remanufacture-friendly.

- Enables creative, flexible designs.

- Enables affordable repairs.

- Cost efficient compared to other materials.

- Well-established manufacturing and recycling infrastructure and workforce.

- Stainless Steel Sheet

- Stainless Steel Plate

- Stainless Steel Tube

- Stainless Steel Pipe

- Stainless Steel Bar

- Stainless Steel Rod

- Stainless Steel Coil

- Stainless Steel Strip

- Stainless Steel Angle

- Stainless Steel Flat Bar

- Stainless Steel Channel

- Stainless Steel Wire

- Stainless Steel Wire Mesh

- Stainless Steel Rectangular Tube

- Stainless Steel Cable

- Stainless Steel Threaded Rod

Get The Solution

We offer our customers the opportunity to increase profitability by meeting their just-in-time production schedules and offering customized services to meet end-user-specific requirements. Posco Group has always been committed to improving customer service and product quality and providing high-value solutions for customers’ businesses. Satisfying the needs of customers is our daily work goal!